Ecolomondo Headquarters

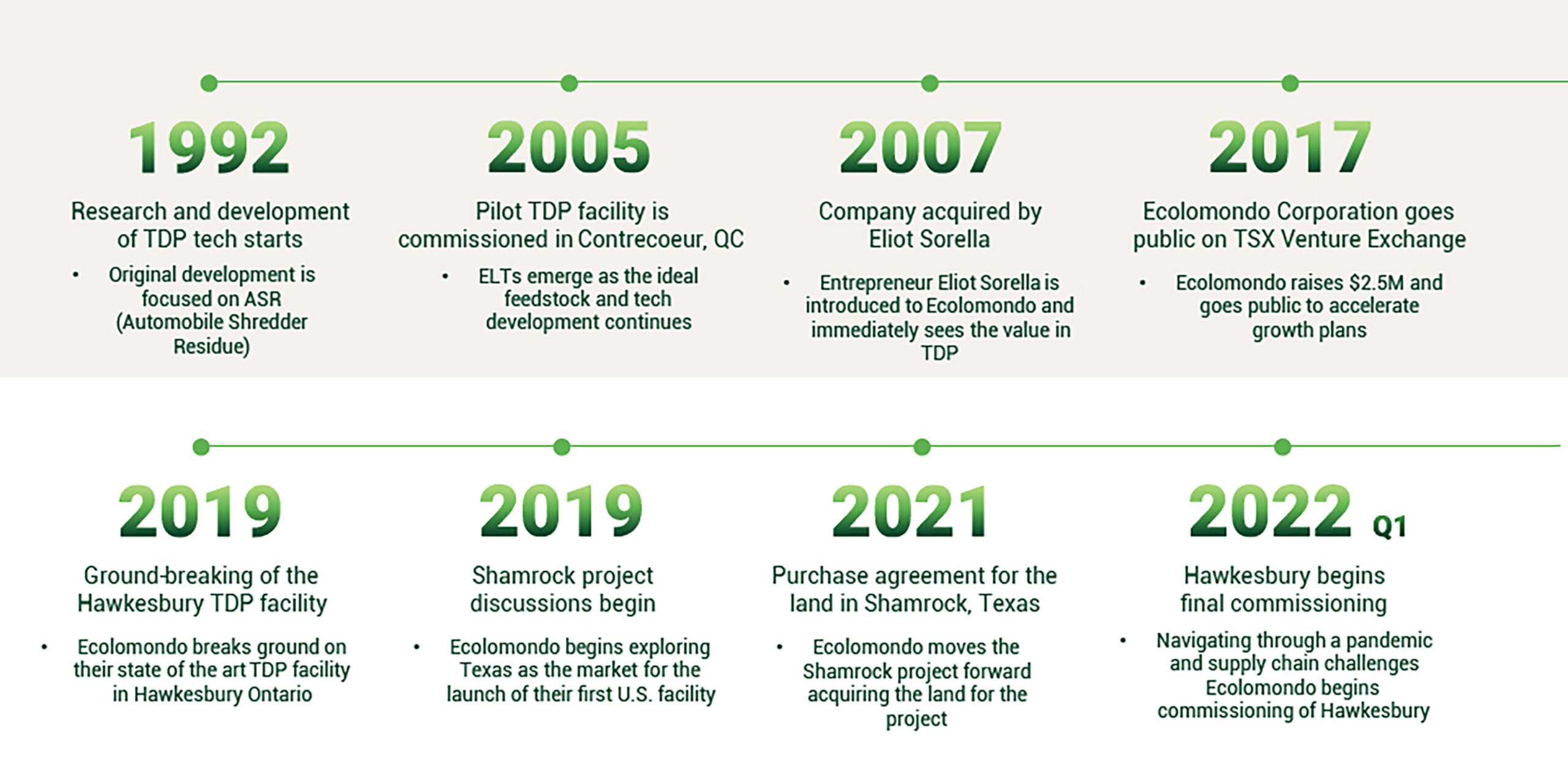

Ecolomondo Corporation began over 25 years ago by Richard Bouziane and Rodier Michaud. Ecolomondo was founded to acquire and develop a new green recycling technology. As it exists today, it was incorporated in 2007 under the laws of Canada by Executive Chairman Eliot Sorella to acquire the Pilot plant and its intellectual property, located in Contrecoeur, Quebec, Canada.

Ecolomondo Corporation began over 25 years ago by Richard Bouziane and Rodier Michaud. Ecolomondo was founded to acquire and develop a new green recycling technology. As it exists today, it was incorporated in 2007 under the laws of Canada by Executive Chairman Eliot Sorella to acquire the Pilot plant and its intellectual property, located in Contrecoeur, Quebec, Canada.

Ecolomondo Corporation went public in 2017 on the TSX Venture Exchange and is listed under the symbol “ECM.”

Our technology transforms hydrocarbon waste into renewable commodity products. Ecolomondo is selling turnkey facilities using technology based on the Thermal Decomposition Process, also called TDP. Our technology is proprietary, green and responds to today’s environmental challenges created by inefficient management of hydrocarbon waste.

Today, hydrocarbon waste represents approximately 34% of all landfilled waste. The most common types of hydrocarbon waste are tires, rubber, plastics, asphalt roof shingles, automobile shred residue and disposed diapers. Even though TDP will process all types of hydrocarbon waste, Ecolomondo has begun to commercialize by marketing turnkey facilities for scrap tires, because they bring the highest commercial value.

Pilot Plant

Through ongoing research and development, we have developed an industrial-scale plant, which we call “Pilot”. It consists of two reactors, located in Contrecoeur, Quebec, Canada. At Pilot, reactor payloads showed that they are capable of processing 6.5 tons of tire waste in less than 8 hours. Thanks to our Pilot Facility we have been able to repeatedly validate all technology upgrades especially in the areas of reactor payloads, cycle times, production yields and process parameters.

Through ongoing research and development, we have developed an industrial-scale plant, which we call “Pilot”. It consists of two reactors, located in Contrecoeur, Quebec, Canada. At Pilot, reactor payloads showed that they are capable of processing 6.5 tons of tire waste in less than 8 hours. Thanks to our Pilot Facility we have been able to repeatedly validate all technology upgrades especially in the areas of reactor payloads, cycle times, production yields and process parameters.

Even though most tests performed at our Pilot Plant were on tires, Pilot has been able to validate that TDP will also decompose other types of hydrocarbon waste including plastics, disposed diapers, asphalt roof shingles, and car fluff.

PROFITS FROM WASTE

Ecolomondo Hawkesbury

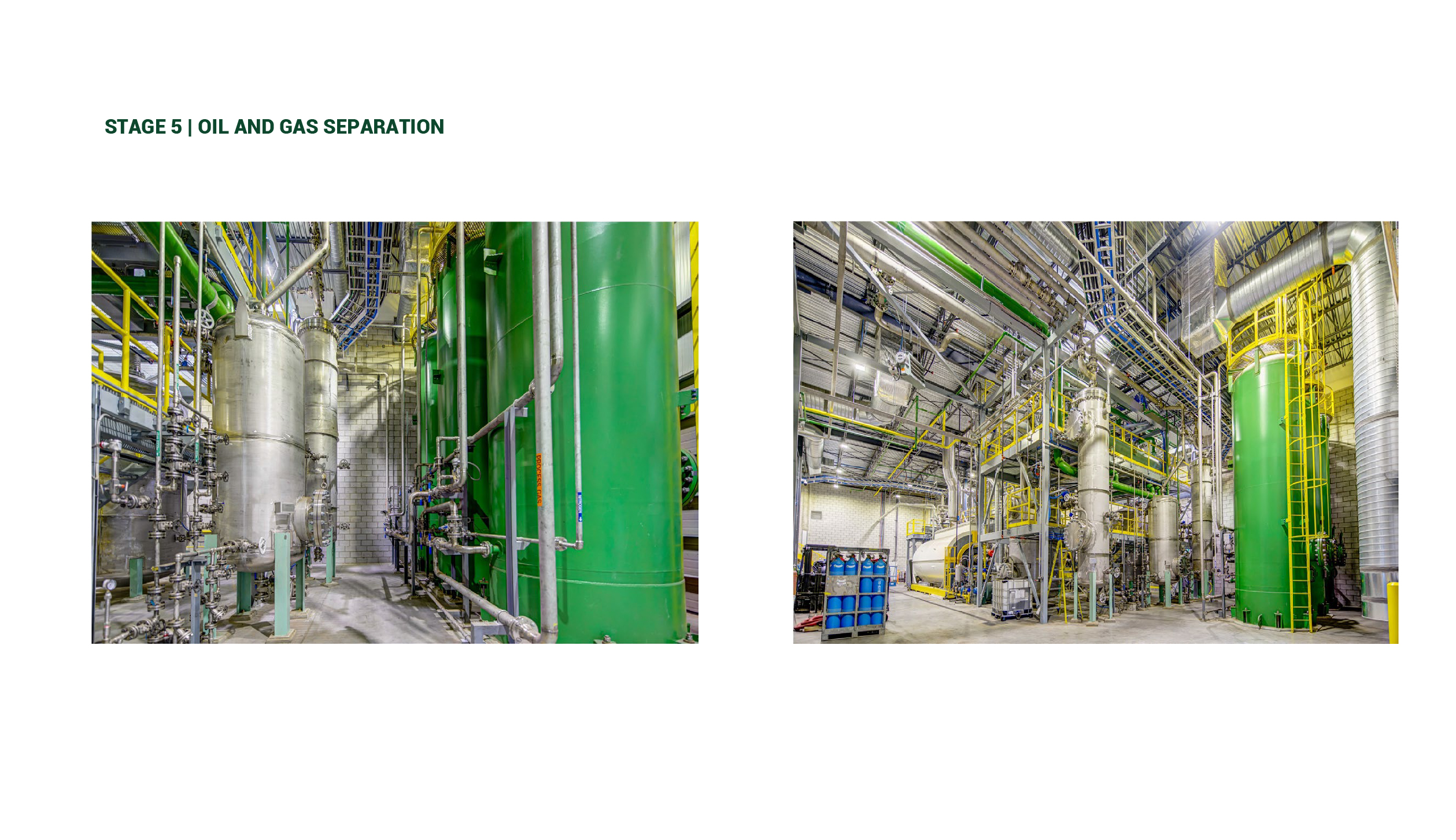

The Hawkesbury TDP facility redefines the way scrap tires are being processed. It produces renewable products in a much cleaner and safer environment, all at a cheaper cost. It is comprised of four processing departments (shredding, thermal processing, recovered carbon black processing, oil fractionation). The Hawkesbury facility is capable of processing a minimum of 14,000 tons of tire waste per year and produces 5,300 tons of recovered carbon black, 42,700 barrels of oil, 1,800 tons of steel, 1,600 tons of process gas and 850 tons of fiber.

“This plant, which is a first of its kind, will demonstrate the full potential of Ecolomondo’s TDP technology.” says Eliot Sorella, Executive Chairman of the Company.

Ecolomondo has proven its TDP technology can operate at scale and produce high-quality end products

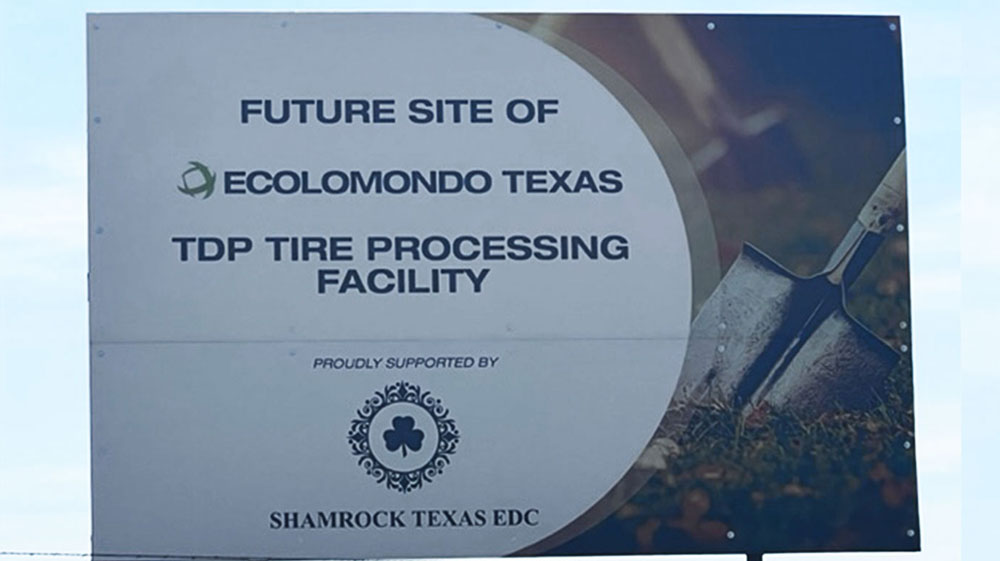

Ecolomondo Shamrock

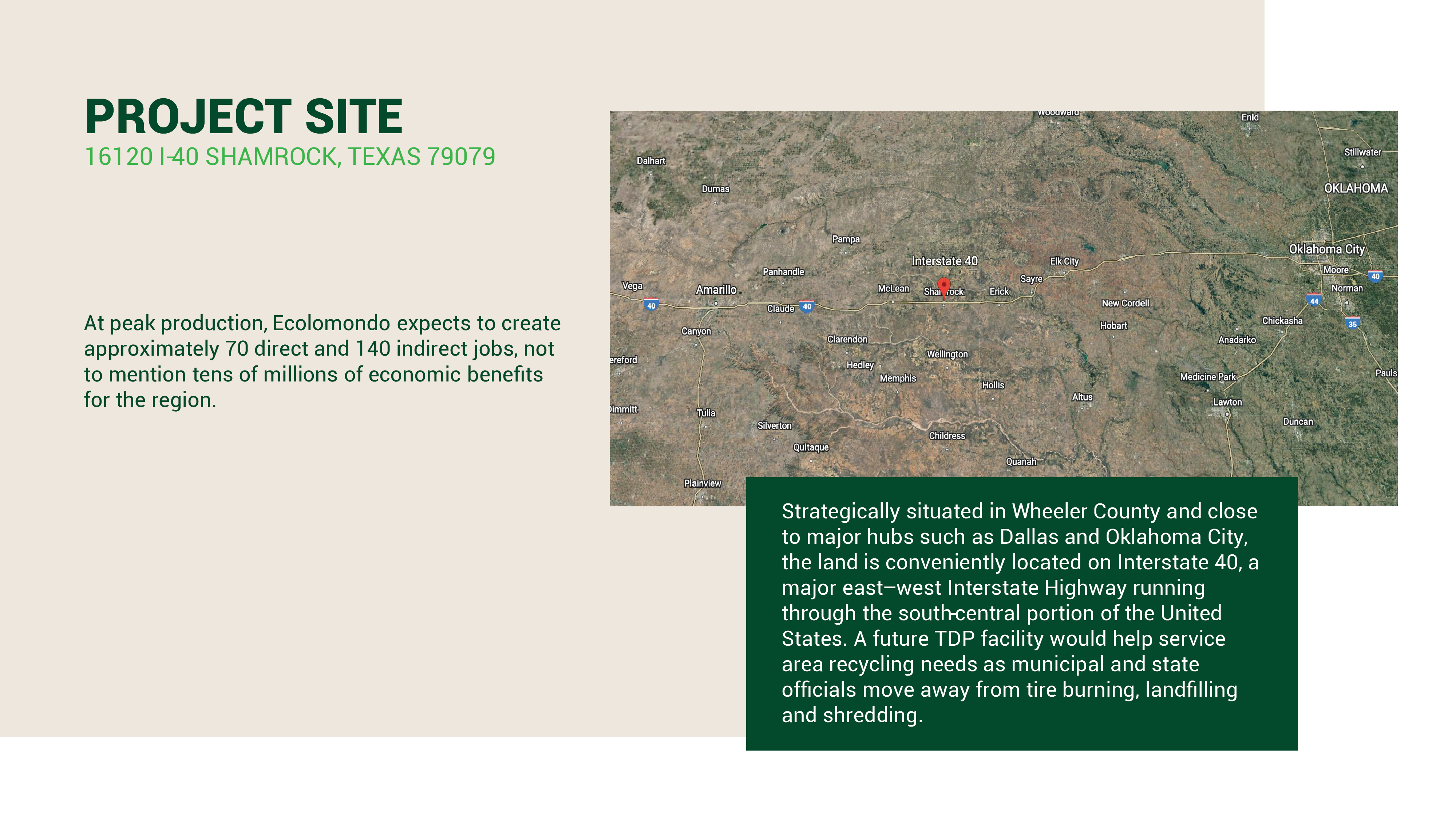

In line with its global expansion strategy, the Company is planning its next project, a six-reactor TDP facility to be located in Shamrock, Texas. Towards this end Ecolomondo has finalized the land purchase agreement of a 136.76 acre parcel of land in Shamrock, Texas as the site for the TDP plant process capacity of the Shamrock facility is projected to be approximately 50,000 metric tons of end of life tires, three times the size of the Company’s Hawkesbury (Ontario) plant. Shamrock will have the largest capacity of any pyrolysis plant on the planet, it will yield approximately 15,900 metric tons of recovered carbon black, 128,100 barrels of oil, 5,400 metric tons of steel, 2,550 metric tons of fiber and 4,800 metric tons of syngas.

In line with its global expansion strategy, the Company is planning its next project, a six-reactor TDP facility to be located in Shamrock, Texas. Towards this end Ecolomondo has finalized the land purchase agreement of a 136.76 acre parcel of land in Shamrock, Texas as the site for the TDP plant process capacity of the Shamrock facility is projected to be approximately 50,000 metric tons of end of life tires, three times the size of the Company’s Hawkesbury (Ontario) plant. Shamrock will have the largest capacity of any pyrolysis plant on the planet, it will yield approximately 15,900 metric tons of recovered carbon black, 128,100 barrels of oil, 5,400 metric tons of steel, 2,550 metric tons of fiber and 4,800 metric tons of syngas.

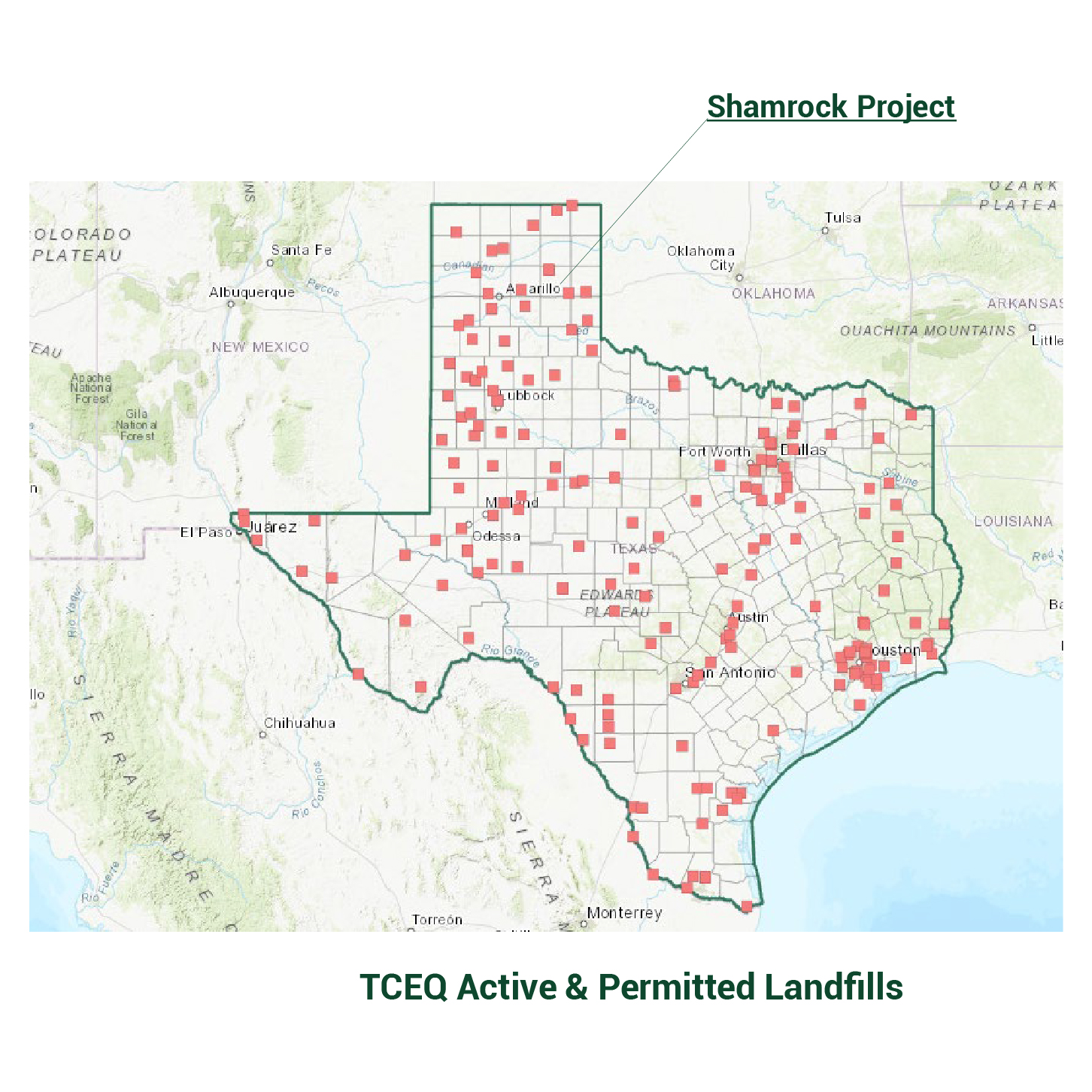

Strategically situated in Wheeler County and close to major hubs such as Dallas and Oklahoma City, the land is conveniently located on Interstate 40, a major east–west Interstate Highway running through the south-central portion of the United States.

A future TDP facility would help service area recycling needs as municipal and state officials move away from tire burning, landfilling, and shredding.

Major cities nearby